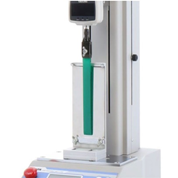

The Peel Adhesion Tester - UniTest is highly configurable tester designed to perform wide range of tests including peel adhesion test. The tester can conduct 90 degree, 180 degree and loop tack peel adhesion tests.

With a rugged design suitable for laboratory and production environments, the tester can measure applications up to up to 150kg (1.5kN). Satisfy various test methods through an easy-to-use 7 inch or 10 inch touch screen allowing the configuration of test speed, force and distance limits, cycling, preload, and many other functions, all protected by a password. Modularity extends to the controller functions as well. Individual functions, such as travel measurement, cycling, load holding, etc., may be purchased either upfront or enabled in the field through an activation code. This platform allows for custom configuration as appropriate for the application and budget. Collect force and travel data, plot and analyse the results, and control test stand motion via touch screen or PC- based, fully control the stand through power full a Lab VIEW flat form software.

Peel Adhesion Tests

With the help of grips and accessories, the U0001 – UniTest can perform various peel adhesion tests including:

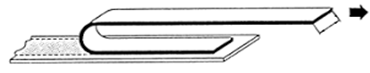

Peel adhesion (180 degree) at 300mm per minute - ASTM D3330 Test Method A / PSTC-1

This test method quantifies the permanence of adhesion or peelability of self-adhesive pressure sensitive materials. The test strips should be 25 mm wide and have a minimum length of 175 mm in the machine direction. The test procedure includes fixing the test plate and strip in the machine so that the angle of peel is 180º. The machine is set at 300mm per minute jaw separation rate. Peel adhesion (180º) is the average result for the strips tested in Newtons per 25mm width.

Low speed release force - ASTM D3330

FTM 3 is used to determine the force required to separate the release backing from the pressure sensitive adhesive coated face material. The test procedure includes fixing each strip by double sided tape (cover the full test area of the sample), so the laminate can be peeled apart at an angle of 180º. The Tester has a low speed feature to perform this test.

180-degree peel Attachment

25 mm – 180-degree, 300 mm/min or lower speed option

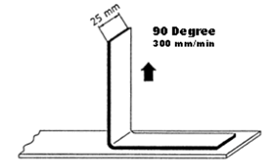

Peel adhesion (90 degree) at 300mm per minute – ASTM D3330 Test Method F

The purpose of this test is to compare the adhesive response of different laminates. Measuring peel adhesion at 90º normally gives a lower value than at 180º and allows values to be measured for materials normally giving paper tear. Adhesion is measured 20 minutes and 24 hours after application, the latter being considered as the ultimate adhesion. Test strips should be 25 mm wide and have a minimum length of 175 mm in the machine direction.

90-degree peel Attachment

25 mm – 90-degree, 300 mm/min

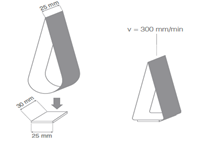

'Loop' tack measurement – FINAT 9

The method allows the end user to compare the "initial grab" or "application tack" of different laminates and can be extremely useful to those working with automatic labeling equipment where this property is of particular importance. The test procedure starts by holding the two ends of the adhesive coated facing material strip and form the strip into a loop, adhesive surface outermost, by bringing the two ends together. Then clamping the ends of the loop for a distance of 10mm into the top jaw of the tester leaving the loop hanging vertically downwards. The sides of the jaw should be protected from the adhesive coating.

Loop Tack Fixture

Loop Tack Pull Test – 300 mm/min

Silicone coated substrates for self-adhesive laminates

This test offers a method of assessing the suitability of a siliconised (or other release) backing material for pressure sensitive lamination.

180 degree - silicone coated substrates for self-adhesive laminates: subsequent adhesion

This test method describes a technique whereby the effect of the release surface on the adhesive properties can be assessed. It is of particular interest both to manufacturers of release paper and also to pressure sensitive laminate manufacturers in determining the key and degree of cure of the release system.

Grips and attachments

1.25" wide film grip - MAR-G1008

3" wide film grip - MAR-G1015-1

5" wide film grip - MAR-G1015-2

Features of the Peel Adhesion Tester

- Selectable speed setting

- Upper and lower travel limit switches

- 7 inch touch screen (or optional 10 inch screen)

- Android based app

- PC control with LabVIEW based software

- Test results: mean, deviation, maximum and peak

- Results are saved in pdf format for printing

- Easily moveable and transportable

- Auto recognizing of up to 5 load cells

- Password protection of test parameters

- Stepper motor-driven, producing smooth and quiet operation with no speed variation under load

- USB output of force vs. time or force vs. travel.

- Compact, Ergonomic design with smart cable management

Optional Features

Individual functions, such as travel measurement, cycling, load holding, etc., may be purchased either upfront or enabled in the field through an activation code. This platform allows for custom configuration as appropriate for the application and budget. Collect force and travel data, plot and analyse the results, and control test stand motion via touch screen or PC- based with LabVIEW flat form software.

| Features |

Description |

| Force gauges |

Wide range of force gauges available from 50 gF full scale to 2,000 lbF |

| FollowMe™ |

Crosshead movement responds to manually pushing or pulling on the force gauge shaft or load cell. Increasing force produces greater speeds. Ideal for setups and quick positioning. |

| Travel indication |

Travel is indicated on the control unit display, with output via USB. The most recent position is displayed upon powering on. |

| Computer control |

The UTM may be fully controlled by a PC through a Lab View program. |

| Programmable travel limits |

The stand stops at or cycles between programmable upper and lower travel distances. |

| Overload protection |

Protects a force gauge or force sensor against overload. Program the desired percentage of full scale of the gauge in kgs. |

| Auto return |

The crosshead moves to a limit switch, force set point, travel position, or break, then stops and reverses direction at full speed to the opposite limit. |

| Cycling / dwell time |

Same as auto return, but with the ability to program up to 100,000 cycles. Programmable dwell time for upper and lower limits (set independently) can be set up for up to 10,000 seconds. |

| Low speed extension |

Extends the standard speed range down to 0.02 in/min (0.5 mm/min) |

| Break detection |

Crosshead stops at a sudden drop in force. Programmable percentage of peak force. |

| Load holding |

Dynamically adjusts the crosshead position to maintain a programmed load for an indefinite or specified period of time. |

| Profiles |

Save and recall sets of test parameters, such as speeds, travel limits, preloads, etc. Up to 50 profiles may be stored |

Warranty and Caibration services

Our Preventive Maintenance and Calibration (PM&C) program has been designed to make the maintenance and calibration of your valuable testing equipment more cost effective by preventing breakdowns and downtime by regular calibration, service and replacement of defective parts. Take to us about this today.

tags: adhesive test, adhesive test equipment, adhesive test machines, adhesive tester, adhesive testing, positest pull-off adhesion tester, coating adhesion tester, portable pull-off adhesion testers, pull-off adhesion tester, automatic adhesion tester