The Gelbo Flex Lint Tester with Particle Counter is to measure the number of loose fibers (lint) shed from non-woven materials. Which is in a 30 second time period of flexing. It is important that non-woven textile materials must have a low tendency to lint. Thus, ensuring their quality. This instrument is also known as the dry state lint tester. The applications of lint test include testing face masks, surgical gowns, PPE clothing suits, caps, gloves and drapes.

Gelbo Flex Lint Tester with Particle Counter consists of two 82.8mm diameter mandrels, one fixed and the other attached to a moveable arm to perform the flexing action. The moveable mandrel twists and compresses the sample at 60 cycles/min of 180° rotation over 120mm of stroke.

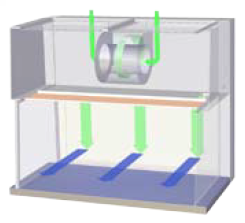

Flexing Chamber measuring 300 x 300 x 300 mm which has removable panels for easy cleaning with built in Isokinetic intake probe (air collector), and HEPA filter to reduce the incoming dust & lint.

Flexing Chamber measuring 300 x 300 x 300 mm which has removable panels for easy cleaning with built in Isokinetic intake probe (air collector), and HEPA filter to reduce the incoming dust & lint.

Particle Counter counts and sorts the particles in real time with relevance to sizing from 0.3 to 25.0μm or 0.5 to 25.0μm. The counter will simultaneously monitor up to 6 environmental sensors such as temperature, humidity, air velocity or differential pressure. These are recorded whilst measuring particles. It has a flow rate of 1CFM (28.3 LPM) and is able to store up to 3,000 data sets including particle and environmental data, plus location time etc. It also prints reports on a built in thermal printer.

Particle Counter counts and sorts the particles in real time with relevance to sizing from 0.3 to 25.0μm or 0.5 to 25.0μm. The counter will simultaneously monitor up to 6 environmental sensors such as temperature, humidity, air velocity or differential pressure. These are recorded whilst measuring particles. It has a flow rate of 1CFM (28.3 LPM) and is able to store up to 3,000 data sets including particle and environmental data, plus location time etc. It also prints reports on a built in thermal printer.

The instrument comes along with a particle counter with an option to choose from:

- 3100+ Measuring Channels (C6): 0.3, 0.5, 1.0, 5.0, 10.0, 25.0μm

- 5100+ Measuring Channels (C6): 0.5, 1.0, 3.0, 5.0, 10.0, 25.0μm

Optional Particle Measuring Channels:

-

IDM-G0005-OP1 - 3100+ (C8) Measuring Channels: 0.3, 0.5, 0.7, 1.0, 3.0, 5.0, 10.0, 25.0μm

-

IDM-G0005-OP2 - 5100+ (C8) Measuring Channels: 0.5, 1.0, 2.0, 3.0, 5.0, 7.0, 10.0, 25.0μm

- IDM-G0005-OP3 - Measuring Channels: 5, 10, 20, 30, 50, 100μm

The Purge Filter is fitted behind the Moving Shaft Housing, and a flexible hose is connected from the Purge Filter to the back of the Particle Counter. When connected, the Purge Filter is used alongside the Gelbo Flex Tester with Particle Counter to reduce the amount of airborne dust/lint within the flexing chamber throughout testing.

Dry State Lint tester

Gelbo flex tester with particle counter is useful to measure the lint and other particles generation of nonwovens. And also other textile materials in the dry state by Gelbo flex testing methods. The Gelbo flex tester provides twisting and compression actions for the specimen. This releases fragments and lint during flexing in the air stream. The machine records these and classifies them in the particle counter. This instrument is a fast and accurate instrument. This test is also useful for other materials like tissues.

The sample is subjected to repetitive twisting and compression cycles, the air is withdrawn from the testing chamber and particles in the air stream are counted and classified with the laser particle counter.

Particle Counter Software

LMS Express 7 allows users to manually download data directly from Lighthouse instruments or import Lighthouse Secure Data files from supported counters.

- Manual data download from Lighthouse Portable Particle Counters via COM ports and Network Ports

- Exports data tables and reports to excel (*.XLS) or CSV

- Exports graphs to BMP, JPEG, and more

- Easy unit conversion

- Localized dates and numbers

- Includes database with archiving feature

Flex testing for textile/ nonwoven materials

The Gelbo Flex Tester with Particle Counter is used to subject a sample material to combined twisting and compression movements. During this flexing period, air is withdrawn from the chamber and particles in the air stream are counted and classified on the particle counter for evaluation.

- Lint: fibre fragments released during handling

- Linting: release of lint and other particles during handling

- Coefficient of linting: record of the particle count applied to all or to part of the measurement channels

Test Specimens

Prior to conducting a test, the operator should wear rubber gloves when handling the test specimens. All preparation of the test pieces shall be made in a clean room environment, and observing the specifications given in ISO 554. When selecting your samples to be tested, make sure the material is clean, dry and free from environmental contamination. Seven samples should be equally cut out, with only 5 samples being tested. The other two samples (top and bottom) are only required to protect the samples while not in use. Keep samples clean (preferably in a plastic bag) prior to testing, and make sure they are free from any folds or wrinkles. Cut out two sets of 7 test pieces in 220 ± 1mm x 285 ± 1mm using cutting template (as shown below) Mark one set on one face Side A and the other set on the other face Side B.

Roll out the test piece around the sample mounting fixture with the longer dimensions corresponding to the circumference. Glue the edges on a width of 0.5cm using double sided tape, with the diameter of the tube equalling 89mm.

Gelbo Flex Testing Procedure

- Power on machine and press the HOME button to ensure the mandrels are set in their starting position (188 ± 2mm apart)

- Attach the test piece tube to both mandrels with minimum handling and maximum care, using Mandrel clamps provided

- Close the flexing chamber and set up to ensure the flexing unit is set to run for longer than the particle counter total cycle times (eg. 5.30 mins for 10 x 30s run)

-

Start the testing by pressing the START button on the Gelbo Flex unit and the START icon on the Particle Counter touch screen simultaneously. The instruments should run until 10 consecutive periods of 30s have been completed.

-

When the test has finished and the flexing unit and particle counter have both stopped, remove the test piece, and clean out the flexing chamber before testing the next piece.

-

Print results by selecting the PRINT icon in the Particle Counter.

-

Repeat this procedure for all ten test pieces. Five from side A and five from side B.

Horizontal Laminar Airflow Cabinet

The Gelbo FLex Tester requires a clean environment to conduct the test accuractely. If the test is to be conducted in an unclean enviornment including factories, production facilities. A Laminar Flow Cabinet is used wherein the Gelbo Flex Unit is placed inside the cabinet. These horizontal flow models filtered air is then passed through the main chamber of the clean bench in a horizontal laminar (unidirectional) air stream and is exhausted through the front opening of the cabinet.

Options of laminar Flow cabinets:

Room air is taken from the top of the clean bench through a disposable pre-filter with 85% arrestance. The air is forced evenly across the ULPA filter, creating a clean stream of air within the workzone.

- Stable & self-compensating flow

- ULPA filter (up to ISO Class 3)

Air is forced evenly across the ULPA/H14 filter(s); the result is a stream of clean laminar air within the workzone of the clean bench; this dilutes and flushes all airborne contaminants from the interior.

- Filtering won’t let particles greater than 0.3 μm pass through.

Proven Product Protection

Horizontal laminar air flow with ULPA filtration, >99.999% at to 0.3 microns, provides superior product protection.

Key features

-

ULPA filters (per IEST-RP-CC-001.3) tested to a typical efficiency of >99.999% for 0.1 to 0.3 micron particles are better than HEPA filters. ULPA filters last as long as conventional HEPA filters and have similar replacement costs.

-

The laminar flow clean benches provide ISO Class 3 air cleanliness within the work zone as per ISO 14644.1, significantly cleaner than the usual Class 5 classification on clean benches offered by the competition.

-

The intelligent blower system maintains airflow as the filter becomes loaded, ensuring optimum efficiency and product protection.

-

An additional disposable pre-filter traps large particles in the inflow air prior to reaching the main filter, protecting against damage and prolonging filter life.

-

These products are manufactured for the most demanding laboratory applications. All components are designed for maximum chemical resistance and enhanced durability for a long service life. The main body of the clean bench is constructed of industrialgrade electro-galvanized steel.

tags: air particle test, air particle test equipment, air particle test machines, air particle tester, air particle testing, lint tester, lint particle testing, mask testing machine, face mask tester, flex test equipment, flex tester, flex testing, astm f392

ULPA filters (per IEST-RP-CC-001.3) tested

to a typical efficiency of >99.999% for

0.1 to 0.3 micron particles are better than

HEPA filters. ULPA filters last as long as

conventional HEPA filters and have similar

replacement costs.

All Esco laminar flow clean benches

provide ISO Class 3 air cleanliness within

the work zone as per ISO 14644.1,

significantly cleaner than the usual Class

5 classification on clean benches offered

by the competition.

The intelligent blower system maintains

airflow as the filter becomes loaded,

ensuring optimum efficiency and product

protection.

An additional disposable pre-filter traps

large particles in the inflow air prior

to reaching the main filter, protecting

against damage and prolonging filter life.

All Esco products are manufactured

for the most demanding laboratory

applications. All components are

designed for maximum chemical

resistance and enhanced durability for a

long service life. The main body of the

clean bench is constructed of industrialgrade

electro-galvanized steel.