International Standard IDM Laboratory Heated Presses are used by laboratories around the world for pressing, forming, molding, laminating, embossing and bonding of various material samples between two heated platens.

The current IDM, LHP Series has been expanded and improved with more sizes, options, features, and quality performance than others.

Standard choices also now include two-column and four-column, bench top and floor standing, and manual, Hydraulic Power Unit, or automatic plc presses with clamping capacities from 10 to 60 tons. Automatic "Auto Series" presses include user-friendly PLC control system and integral safety enclosures. Accessories include new self-contained, electrically operated AutoPak hydraulic power unit for Two digital temperature controllers enable the platens to be heated or cooled and even set process times for heating and cooling. One the control panel a digital panel meter connected to a pressure transducer is used to display the compression force in (kgf) enabling fast and accurate control of pressure application.

These presses are widely used in:

- Quality and performance testing of physical properties: compression strength, flexural strength, shear strength, flow and color dispersion

- Lab Testing: ASTM test plaque or bar molds for polyethylene and polypropylene

- Laminating

- Other applications: composite molding, compression molding, crushing, encapsulation, extrusion, forming, insert pressing, producing KBr pellets for infrared spectroscopy, metal forming (dimpling), insert molding, oil extraction, pelletizing, specimen preparation, splice molding, splitting chilled oils, transfer molding, and vulcanizing rubber stamps.

Custom Presses

In addition to the model shown on this web site, IDM designs and manufactures a wide variety of custom-made presses and accessories to suit your specific application. Please consult the factory for any equipment not specifically listed on this site.

Available Models

LHP Series M1 models – Hand Pump

The M1 models have been upgraded with a robust design to ensure durability of the instrument. A control panel is fitted with a digital display that specifies in kgf to give you an indication of how much force you are applying. Two temperature controllers for the upper and lower platens are also fitted and display the set point and the actual temperature when running. When the water-cooling option is selected, a timer is also supplied for turning on the water to cool the platens to ambient after a pre-set heating time.

LHP Series M2 models – Electric Pump

The M2 models come with an Electric Operated Hydraulic Pump which is used to raise and lower the compression platens on the Laboratory Heated Press. The electric pump has a flow-control valve to increase or decrease speed of the platens. It also has Advance valve which holds pressure with motor shut off and Return valve which advances cylinder with motor running and returns cylinder with motor shut off. The model has a control panel displaying the real-time force applied along with temperature controllers displaying the temperature of the upper and lower platens.

LHP Series M3 Models – PLC control

The M3 Models comes with the latest design featuring a PLC touch-screen to control various functions of the instrument. This feature allows easy operation like changing the force (kgf) or lowering the platen and eliminates manual operation. It also comes with two temperature controllers to control the temperatures of the upper & lower platens.

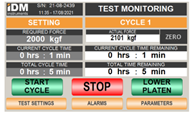

PLC Touch-screen

The PLC Touch-screen ensures digital control of the instrument ensuring efficiency. By the click of a button, the platen position & force can be altered before or during the test. It displays in real-time the current force being applied, time remaining for each cycle and the total time remaining. Using the Test Setting function, 5 test cycles can be set by inputting the required force and time for each cycle. The instrument automatically stops after the cycles have been completed.

Models & Specifications

|

Model

|

IDM-LHP0001

|

IDM-LHP0002

|

IDM-LHP0003

|

|

Options

|

IDM-LHP0001-M1 (Hand Pump)

IDM-LHP0001-M2 (Electric Pump)

IDM-LHP0001-M3 (PLC Control)

|

IDM-LHP0002-M1 (Hand Pump)

IDM-LHP0002-M2 (Electric Pump)

IDM-LHP0002-M3 (PLC Control)

|

IDM-LHP0003-M1 (Hand Pump)

IDM-LHP0003-M2 (Electric Pump)

IDM-LHP0003-M3 (PLC Control)

|

|

Control

|

2 - 20 Tonne

|

3 - 30 Tonne

|

5 - 50 Tonne

|

|

Readability

|

20,000 x 10 kgf

|

30,000 x 10kgf

|

50,000 x 10 kgf

|

|

Platen Size

|

300 mm

|

300 mm

|

300 mm

|

|

Temperature Range

|

300ºC ± 1% FS

|

|

Daylight

|

|

150 mm

|

|

|

Connections

|

415 VAC @ 50 HZ, 3 Phase

|

Optional Items

|

Option

|

IDM-LHP0001

|

IDM-LHP0002

|

IDM-LHP0003

|

|

Temperature Range - 400ºC

|

IDM-LHP0001-OP1

|

IDM-LHP0002-OP1

|

IDM-LHP0003-OP1

|

|

Daylight - 200 mm

|

IDM-LHP0001-OP2

|

IDM-LHP0002-OP2

|

IDM-LHP0003-OP2

|

|

Platen Size - 400 mm

|

--

|

IDM-LHP0002-OP3

|

IDM-LHP0003-OP3

|

|

|

IDM-LHP0001-OP3

|

IDM-LHP0002-OP4-1

(Platen Size 300 mm)

IDM-LHP0002-OP4-2

(Platen Size 400 mm)

|

IDM-LHP0003-OP4-1

(Platen Size 300 mm)

IDM-LHP0003-OP4-2

(Platen Size 400 mm)

|

|

The water-cooled platens are fitted onto the instrument at time of manufacture, and allow the platens to cool at a faster rate also comes with Water Solenoid Valve

|

|

Safety Enclosure

|

IDM-LHP0001-OP4

|

IDM-LHP0002-OP5

|

IDM-LHP0003-OP5

|

|

Safety Enclosure is an outer cover to ensure maximum safety and auto-stop function when the enclosure is open.

|

|

Heat Ramp Temperature Controller

|

Consult with IDM for this option

|

Connection of Water Cooling - optional

- Cold Water Connection: (½“ Hose barb)

- Steam Trap Connection: (½” OD Tube)

Looking from the front, the left hand side pipes are the water cooling outlets, where super-heated steam and water will flow from.

On top of the machine is a solenoid water valve. This has an inlet barb fitting attached to suit ½ inch hose. You will need to connect some high pressure hosing to the inlet to provide the flow of water with no restrictions.

In regard to all connections for the water (incoming and outgoing) it is recommended to use high temperature high pressure hosing in order to cope with the super-heated steam and the cold water pressure being on at all times (subject to rising heat from the machine whilst in operation).

The fittings for the outlet (½” OD) hose connection must be either be soldered, or attached with a compression fitting. DO NOT just use hose clamps to hold the hose onto the outlets.

Caution needs to be taken on the insulation of the water hoses because once the platens are hot and water is circulated through the platens, the existing water is High Pressure Steam until the platens cool down. A possible exhaust pipe may be necessary to be fitted.

Optional Items

- IDM-LHP000x-OP1: Laboratory Press Platens Water Cooled - 300 x 300mm (Optional)

- IDM-LHP000x-OP3: Temperature Range 400°C

- IDM-LHP000x-OP4: Platen Size - 400mm x 400mm

- IDM-LHP000x-OP5: 200mm Daylight

- IDM-LHP000x-OP6: Temperature Range 430°C per platen

- IDM-LHP000x-OP7: Platen Size - 500mm x 500mm

- IDM-LHP000x-OP8: Safety Enclosure

- IDM-LHP000x-OP9: 2 x Heat Ramp Temperature Controllers

The objective of compression molding is to produce test specimens or sheets that are both homogeneous and isotropic.

The Laboratory Press is designed for the forming of test samples under pressure and heat between two platens.

- Turn on isolator switch to power machine.

- Set the upper and lower temperatures on temperature controllers to thedesired value.

- Turn heating switch to ON position to begin heating.

- Wait until temperature reaches set point. Red actual temperature should match Green set point temperature on both upper and lower platens.

- Ensure appropriate personal protective equipment is used. Temperature resistant gloves (Kevlar or similar), safety glasses, non-flammable clothing. If possibility exists for sample to be ejected, guarding should be installed. This is available as an option.

- Place objects to be pressed onto lower platen as central as possible.

- Actuate the hydraulic cylinder with hand pump or electric/hydraulic pump.

- After samples have been pressed for required time, relieve pressure on cylinder to lower platen.

- Turn off heating switch to stop heating

- Allow platens to cool before removing and installing new samples.

- Optional coolant circuit may be used to rapidly cool down platens.

- Turn off heaters and isolate power when not in use.

Overload Protection

This unit has been set with an overload protection at the capacity rating of the machine e.g. 20 Tonne. Once the capacity of the machine is reached, an alarm light will illuminate on the digital force display and the hydraulic pump will turn off.