A case study of how we designed and manufactured a custom Constant Load Pounding Tester for Royal Dutch Shell Plc.

Case Study Overview

Royal Dutch Shell plc, commonly known as ‘Shell’, a British-Dutch multinational oil and gas company is a client of IDM Instruments. Shell, India wanted to test foam samples for loss in thickness and loss in hardness as per ASTM D3574 and ISO 3385. Shell required a custom model with a twin head rather than the standard model. Read how did we make his happen.

Royal Dutch Shell plc, commonly known as ‘Shell’, a British-Dutch multinational oil and gas company is a client of IDM Instruments. Shell, India wanted to test foam samples for loss in thickness and loss in hardness as per ASTM D3574 and ISO 3385. Shell required a custom model with a twin head rather than the standard model. Read how did we make his happen.

Advanced features required by Shell, India

The standard F0021 – Constant load pounding machine suits testing standards like ISO 3385 and ASTM D3574. These standards require 20 hours of continuous testing. This was a concern as the power consumption was high. Especially because the Research and Development team at Shell, India continuously tested different compositions of the materials. As a result, only one sample would be tested at one time and the turnover time was longer than ideal.

This is when Shell, India contacted IDM Instruments for a custom machine that could test two samples at the same time.

Our approach

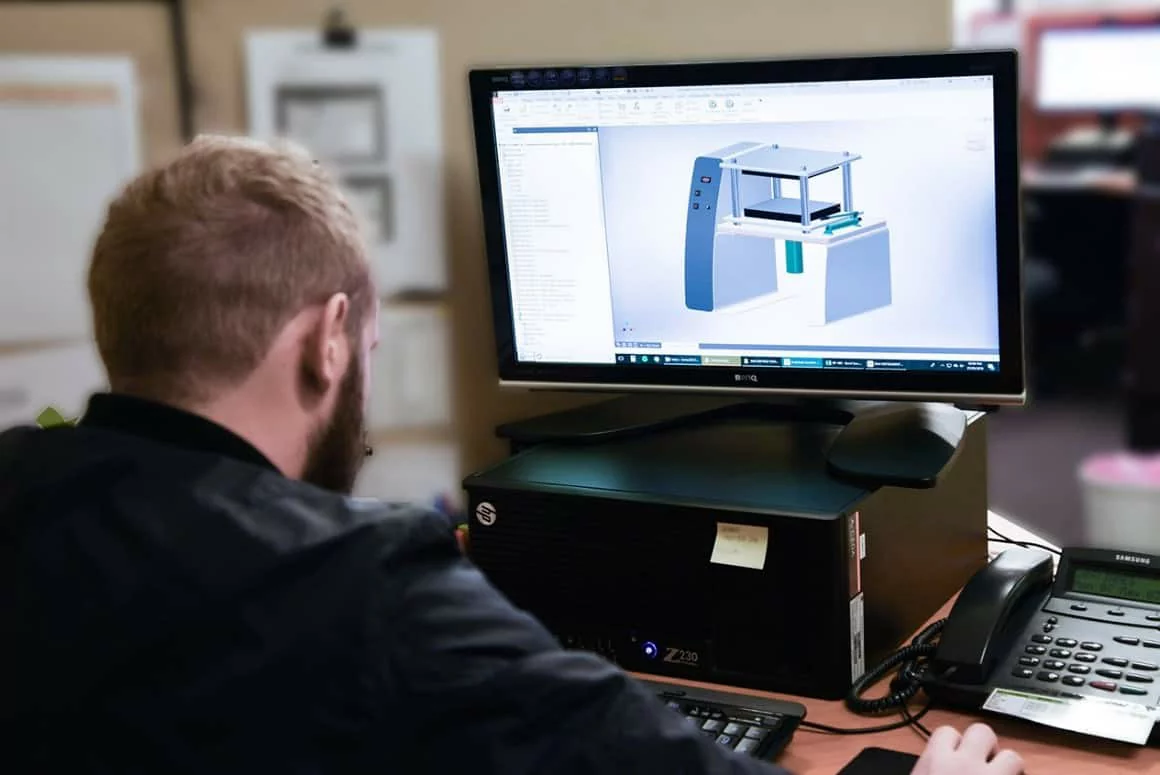

Experts from our design, engineering and production team collaborated to identify possible solutions to fulfil the custom requirements. F0021 – M2 i.e., Constant load Pounding Machine with a dual testing capacity was developed.

Result

Our Technical Sales team in India presented the proposed solution to the Quality Head and Technicians – Shell India and Shell Singapore. Impressed with the modular design and the capabilities of the Custom Constant load Pounding Machine, Shell agreed to proceed with the purchase of the equipment. Shell could save upto 20 hours worth of electricity, manpower and other resources because fo the dual-cpacibility of the F0021.

Why we take custom requirements seriously?

Research and development (R&D) is at the heart of IDM Instruments. We have been improving our machines with newer technologies, designs to supply machines that always exceed expectations.

Our long-term relationship with Shell

For a few decades, we have been supplying testing solutions to various branches of Shell across the globe. By providing prompt support to the company along with yearly calibrations and servicing, we aim to be Shell’s partner in their quality testing journey.

Need a Custom Machine? Contact Us Today.

F0021 – Constant load Pounding Machine – an overview

The Constant Load Pounding Machine is used for the determination of loss in thickness and loss in hardness of flexible cellular materials intended for use in upholstery. This test provides a means of assessing the service performance of flexible cellular materials used in load-bearing upholstery. It adheres to fatigue testing as per ASTM D3754 and ISO 3385 to evaluet the test sample for dtermination of thickness loss .