The Foam Compression Tester uses deflection force on the flexible cellular polyurethane. This instrument allows performing the ILD or IFD of flexible cellular polyurethane. Which is a common test as per ASTM, ISO, AS, BS international standards including ASTM D3574.

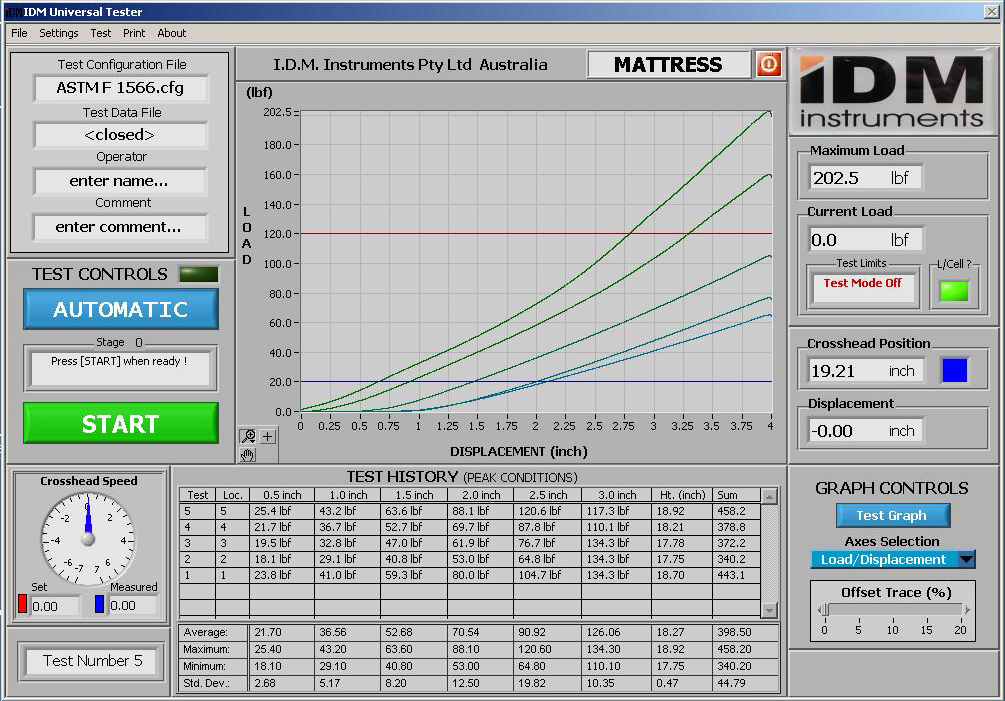

This instrument offers a variety of software features that allow the programming of many parameters. This is because it uses our Universal Tester program. This software package allows the operator to conduct a large range of tests with an almost limitless array of test parameters. And displays test information when used with compatible PC Test Configurations. Thus, the procedure is fully automatic.

Run a test easily. Firstly, enter test scripts and operating parameters in the Configuration Panel. This allows entering a large variety of value types. Some of them include test type, sample piece, sample size, a standard reference. This machine also allows saving these values. Thus, retaining the results.

F0028 - Foam Compression Tester features

- Loading System – closed loop micro computer which drives a ball screw and nut for its vertical movement.

- Load auto-zeroing

- Safety function for overloading provided

- Test area of 500mm wide and not restricted at front and rear

- PC supplied (with 19” flat screen monitor)

Foam Compression Testing Process

The testing operation is divided into three discrete parts:

Entering the System Settings and Test Configurable Requirements: The System Settings are entered during the installation of the equipment and should not have to be changed. The Test Configuration is prepared for each test sample type, and only an experienced operator should only undertake this procedure.

Conducting the Tests: This procedure is fully automated. The operator will be requested to mount a test sample, and to remove it when the test is completed, when conducting multiple tests. A series of one or more tests are usually performed on a particular material to achieve a statistical comparison.

Reporting the Results: When a series of tests is complete, a test report can be generated on a printer.

Foam Compression Software

The Software Program for the Foam Compression Tester is automatic. Thus, after programming the Test Configuration menu, press the “Start” button. This will start the test. The results of the test are displayed on the PC in real-time. Allowing printing or saving them for a later date.

- Data Sampling is adjustable from 1-200,000Hz

- Position or Load control

- Test parameters displayed with graph simultaneously.

- Real time graphic display of data

- Selectable graphical display presentation

- Data can be sent to Excel

- Out of range stop

- Auto return after a test is selected

- Calibration File to calibrate the instrument

- Statistical analysis

- Printable Reports

- Windows based software

- Overlay display of data curve possible during test

- Test Methods programmable

- Other test methods programmable by the operator.

- Cyclic testing with data recording during cycle

Optional Items

- Swivel Platen: 322 ± 2cm² (8” Ø)

- Fixed Platen: 322 ± 2cm² (8” Ø)

- Custom platen fixtures available on request

- Custom size indentor available on request

- Load Cell

- Test area width: 450mm, 750mm, 1,000mm