The Carton Crease Proofer is used for numerical assessment of the creasing qualities of board materials that normally would be converted into cartons on cutting and creasing presses. It comes with robust rules & dies which are of the same quality of those used with a full scale cut and crease machine. The unit is a hand-operated platen press which is designed to fit a two-part creasing die.

The Carton Crease Proofer is useful in ink laboratories. This is because it assists the development of flexible coatings. Which resist cracking on commercial cartons. Thus, allows testing the quality of crease samples. It is quick and easy to do so. The crease samples can be cut using our ruler dies.

Carton Crease Test Procedure

A test piece is creased in the hand-operated platen press to give creases of specified width and depth. The creased test piece is examined for visible faults at the crease and then folded through 180° away from the crease. The test piece is then again examined for faults.The creasing range found gives a direct indication of the quality of a board for carton creasing. The wider the range, the easier it will be for the converter to find acceptable settings on the cutting and creasing press.

The full benefit of this test will be established when the results are relayed to the performance of the boards on converting equipment. Equally, the board mill will also find it beneficial to correlate mill tests results with reports on performance supplied by customers.

Preparation of test samples

It is best to prepare all test pieces in the same atmospheric conditions used to condition the specimens if possible. At least 10 test pieces are to be cut from the specimens. Test pieces must be cut in each of the principle directions of the board and are to be approximately 200mm in length and 50mm wide. For cross-direction folds the crease is at right angle to the machine direction and the test piece should be 73mm wide. This width difference will help to equalize the creasing pressures for the two directions.

Carton Crease Results

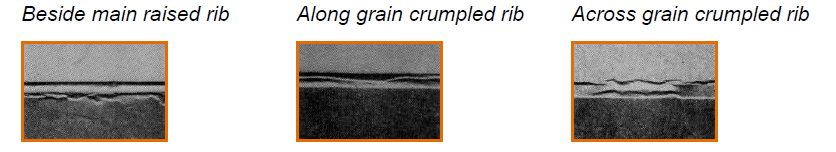

The Carton Crease tester provides in the form of beside main raised rib, along grain crumpled rib and across grain crumpled rib.

- Back of board cracks: Without folding or bending, examine the groove impression on the back of the test piece.

- Liner cracks: Fold the crease through a 180° away from the top surface by hand, and shut between finger and thumb. Then open out to 90° and examine the liner for cracking (use a microscope if necessary)

- If liner cracking is absent, reverse the test piece and examine the inside of the fold for either pressure ridges beside the main raised rib or a crumpled appearance to the rib.

-

If the folds are satisfactory, continue the test using both wider and narrower grooves until the folds show signs of faults.

-

If the folds show either cracking of the back or liner or a pressure ridge, proceed by using only wider grooves.

-

If the folds show a crumpled rib, proceed by using only narrower grooves.

-

Refer to BS 4818 for further examination notes