The Melt Flow Indexer is designed to determine the melt mass-flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic as well as test the high melt temperature such as PC, Fluor plastics, and nylon, but also PE, PP, POM, PS, ABS resin which has low melt temperature. This testing machine is designed to perform tests according to AS, ASTM and ISO standards.

The specimen is melted under high temperature by heating the furnace. The melted specimen flows out a specified hole under the given load. In plastic producing activities, we usually use the melt index to measure the physical properties of the polymer, such as the fluidity or mucosity, etc.

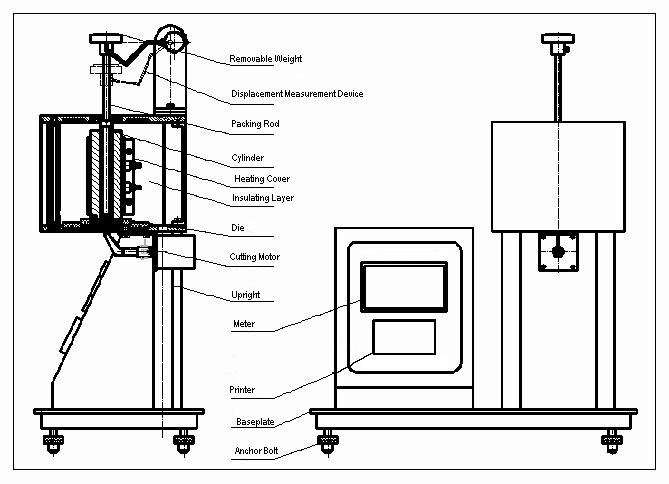

Parts of the Melt Flow Indexer

Monitor: A touch screen LCD. Operate the tester according to the relative dialogue box. Touch the relative dialogue box or button to input the test parameters and the relative page shows the test temperature, the rod displacement and the real-time curve of MVR.

Printer: When the test ends, input the mass value of the melted specimen to check or print the MFR test data as well as check or print the data directly.

PLC: Receive the orders from the touch screen to measure and control the furnace temperature and determine the displacement of the load rod.

Furnace Chamber: Consists of heating cover, cylinder, die load rod and removable weights.

Spatula: Made up of the motor, the cover and the edge. The motor drives by the tester and rotates automatically to make the edge cut the sample so as to avoid the human error of manual cut.

Displacement Sensor: Installed at the upper right back of the tester, together with the load rod, measures the displacement of the load rod.