The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing.

The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD). Which is calculated by determining the force required to deflect a test piece. Which is a percentage of its original thickness using a circular indentor. This applies a force, while also recording the degree of indentation.

As the name suggests, it is called "Universal testing Machine" because it can test tensile and compression of various materials. For example, textiles, rubber, springs, plastic and others. The tests conform with relevant testing standards such as ASTM, ISO, JIS, GB, and many others.

Compression and Tensile Testing

IDM Instruments' UTM comes with fixed dual testing capabilities. Which comprises of compression testing on the inner frame. As well as tensile strength testing on the outer frame. This incorporation of dual testing space design is beneficial. as it eliminates the need of having two machines required for testing. The same machine is useful for both tests. The twin column bench-mounted UTM has a strong and durable frame. Thus, can withstand many years of use. It offers excellent accuracy and ease of use. It operates on the IDM Instruments Pty Ltd software program.

Why is tensile testing important?

Tensile testing is a common method used to test quality of materials. The tensile of a sample is determined by the force required to elongate (applying tension) until it reaches breakage point. For example, a rope is pulled from both ends until it reaches the breaking point. This test helps quality experst determine whether the material/ product would sustain different circumsances it goes through. The minimum tensile strength is determined by the testing standard referred. The applications of tensile testing are limitless. From textile companies to research orgnisations to aerospace companies, tensile tetsing is performed by every quality testing department.

We have so mnay clinets who have used our universal testing machine to test tensile of foam, ropes, wires, plastic, textiles, etc.

What is the importance of the compression test?

The compression test measure the elastic and compressive fracture properties of brittle materials or low-ductility materials. For example, foam samples. Compression tests are also used to determine the elasticity, proportional limit, compressive yield point, compressive yield strength, and compressive strength.

Why choose IDM's Universal testing Machine for tensile and compression testing?

The great benefit of the Universal Testing Machine is the dual testing capability, saving time for operators needing to change between fixtures, as they are fixed onto the machine at their own designated area. The operator needs only to switch a button on the machine to select from tensile to compression, which in turn speeds up production time, test set up time, reduces operator fatigue and decreases possible setup errors.

The twin column bench-mounted Universal Testing Machine has a strong and durable frame to withstand years of use. It offers excellent accuracy and ease of use, operating on the IDM Instruments Pty Ltd software program. The Universal Machine can also be custom made to accommodate a wider testing space, while leaving no restrictions on the sample length that can be tested.

Custom Universal Testing Machine

We also manufacture custom UTM to accommodate as per customer needs. For example, a wider testing space removes the sample length restrictions. This includes cutom load cell capacities that can be expanded or reduced in tonnage based on the test and material being tested.

How to use our universal testing machine?

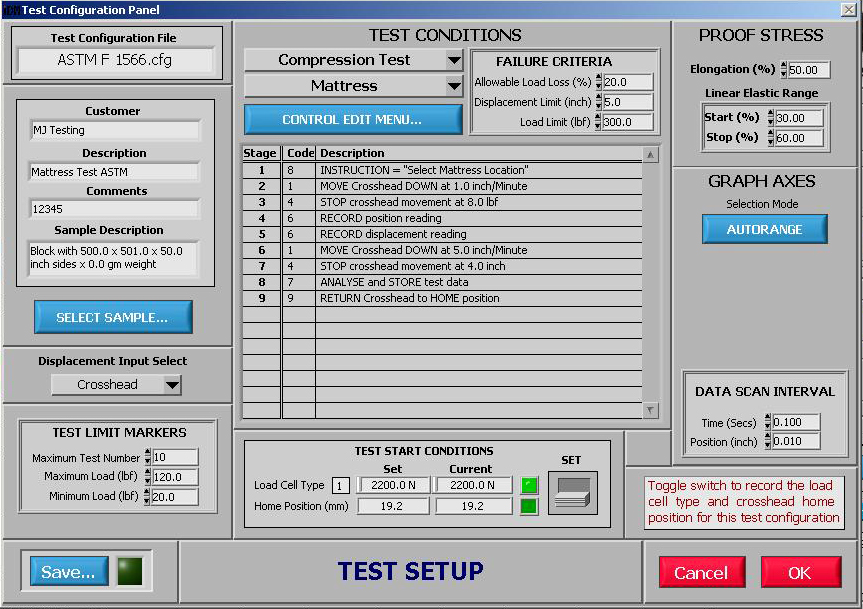

Our UTM offers a variety of software features that allows programming of parameters of the test, operational control and real-time display of the on-going test. This software package allows the operator to conduct a wide range of tests with an almost limitless array of test parameters and displayed test information. The PC based control system uses the Universal Tester program developed by IDM Instruments Pty Ltd.

The test configuration is prepared for each test sample type, as a fully automated process. The test scripts as well as the operating parameters are entered in the Configuration Panel to run a test as per International standard requirements or customer requirements. Values including the test type, sample piece, sample size, standard reference and many more values can all be entered and also saved to be retrieved at a later stage.