Martindale Abrasion Tester commonly referred as pilling or taber abraser determines the wear-resistance. It allows performing grinding tests under pressure of woven and wool blended fabrics, knitted and non-woven fabrics.

The Martindale Abrasion Tester instrument is equipped with two kinds of motion trajectories: LISSAJOUS and a linear reciprocating motion trajectory. The Martindale Abrasion Tester also has a pre-setting count and LCD display. it is simple and convenient to operate. The pilling of textile fabrics is a very complex property because it is affected by many factors that include type of fiber or blends, fiber dimensions, yarn and fabric construction, and fabric finishing treatments. The pilling resistance of a specific fabric in actual wear varies more with general conditions of use and individual wearers than in replicate fabric specimens subjected to controlled laboratory tests.

The Martindale abrasion tester is one of the most popular flat abrasion testers. It is also used for testing pilling propensity. The sample is rubbed against an abradant (usually an abradant fabric) at a certain pressure in continuously changing directions. Rubbing is continued either for a preset number of cycles, after which the mass loss and change in appearance are determined. It may also be continued until a predetermined end point is reached – for example, until two fabric threads are ruptured or a hole is formed. The degree of fabric pilling is evaluated by comparing the tested specimens with visual standards, which may be actual fabrics or photographs of fabrics, showing a range of pilling resistance. The observed resistance to pilling is reported on an arbitrary scale ranging from 5 to 1 (no pilling to very severe pilling).

Martindale Abrasion Test Result

The martindale Barasion Testresult is calculated after the test sample has cmpleted 1000 rubs or cycles using the tester. The higher the result, the more suitable the test sample is for heavier use. “Abrasion resistance” is the number of cycles on a specified machine, using a specified technique to produce a specified degree or amount of abrasion and “durability” is the ability to withstand deterioration or wearing out in use, including the effects of abrasion.

Martindale Abrasion Definitions

Abrasion rub: one revolution of the two outer drives of the Martindale abrasion tester

Abrasion cycle: completion of all the translational abrasion movements tracing a Lissajous figure compnsmg 16 rubs, i.e. 16 revolutions of the two outer drives and 15 revolutions of the inner drive of the Martindale abrasion tester

Inspection interval: number of continuously performed rubs

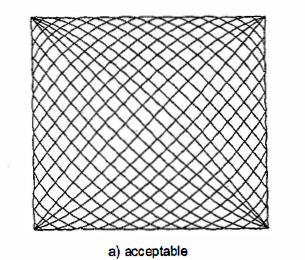

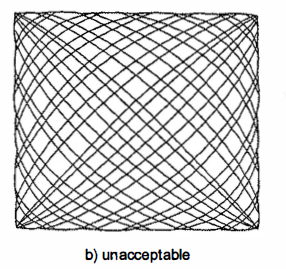

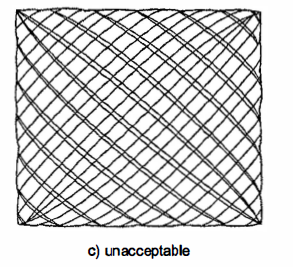

Lissajous figure: Figure created by movement which changes from a circle to gradually narrowing ellipses, until it becomes a straight line, from which progressively widening ellipses develop, in a diagonally opposite direction before the pattern is repeated

Work station: abrading table

Lissajous figure checking process

Obtain the Lissajous figure for each work station by means of the following method.

-

Remove materials from the abrading tables. Cover each abrading table surface with a plain white paper measuring (100 ± 5) mm in diameter of minimum mass per unit area 100 g-m-2 and secure paper to abrading table ensuring the surface is perfectly flat.

-

Insert a steel sleeve of the same diameter as the specimen guide spindle (see figure 3) counterbored to accept the introduction of a refill from a typical ballpoint pen through each of the specimen holder spindle bearings in tum in the specimen holder guide plate, so that the ball tip is resting on the surface of the paper. Set the machine for 16 abrasion rubs to produce one complete Lissajous figure.

-

Draw two parallel lines which just touch the outermost curves on two opposing sides of the Lissajous figure. Draw two more parallel lines for the other two sides making sure the lines intersect at right angles. Measure each side to an accuracy of ± 0,2 mm using suitable means. Check that 31 curves are drawn. It is important to check the symmetry of the Lissajous figures. If the curves run into one another or the spacing is uneven (see figure A.1) consult the machinery supplier.