The Hot Tack tester tests the sealing properties of a wide range of sealable materials. Heat seal applications are highly useful in many industries. Such as packaging, plastic and others. This machine ensures reduction in production time and cost. As it increases the speed of sealing. This is useful for all manufacturers including food manufacturers, film producers, packaging material manufacturers.

Heat sealing is useful for large number of applications. Especially for efficient flexible packaging, seal strength is important. These include polypropylene, cello firms, thermoformed cuprs, trays. As well as laminates and blisters. Also, non woven materials as they can bond by heat. Thus, this machine is useful for all these purposes. This tester ensures accuracy and consistent performance. It guarantees fast and repeatable results free from human intervention.

The tester determines the capability of a heat-seal join. To hang together when it is stressed, at a specified time interval. While still hot from the sealing operation. But before it reaches ambient temperature. The overall design of a package can contribute or detract from the materials ability to provide hot tack during the sealing process. After a heat seal is made, it is probably subject to opening forces such as the weight of the fill. Hot Tack is simply the resistance to seal failure from these forces. This instrument also performs peel strength test by applying force to separate layers.

The Hot Tack Tester refers to the requirements of the ASTM F 1921 such as:

- Equipped with two heated jaws

- Variable and precise control of jaw temperatures, dwell time and pressure

- Variable and constantly rate of grip separation

- Automatic activation of the withdrawal and pull cycles when seal jaws open

- Measures the force required to cause failure in the sealed specimen, and

- Displays measurements in SI units

Importance of Hot Tack Testing

Hot tack knowledge is a considerable concern as package seals must be able to withstand forces and stresses. Which is applied during the form filling process. By assessing the quality of seals key parameters which are sealing pressure, dwell time and temperature. These determine the optimum sealing conditions. Therefore reflected on the production line. This new hot tack technology will aid in the research and development. Especially of flexible films used in the packaging industry. This instruments is a must have in any modern day quality laboratory.

The Hot Tack Tester can be useful in determining certain materials in their ability to perform in commercial applications such as form-fill operations. During these form-fill operations, sealed areas of packages may be subjected to disruptive forces while still hot. These forces can cause breakage during the packing process if the seals have inadequate resistance to such forces.

Hot Tack Testing Procedure

The Hot Tack Tester has been design to determine the strength of heatseals formed between thermoplastic surfaces of flexible webs immediately after a seal has been made. A cycle of the Hot Tack Tester automatically heat seals the specimen, then pulls it apart measuring and recording data such as rate of grip separation (preset by operator) maximum force required to separate specimen after sealing and a cooling curve created over several.

A sample of the test material, having a width of 15mm or 25mm and cut to a length of 300mm, is sealed by applying pressure between two heated jaws under defined conditions of temperature, contact time and pressure. When the jaws are opened, the sealed strip is withdrawn and pulled apart at a set speed until failure of the seal or the specimen takes place, upon which the force required to do so is recorded. Once test parameters have been set and the testing has begun, the operator cannot influence the testing cycle. Hot Tack strength at various sealing temperatures is plotted as the Hot Tack curve of the material tested.

Some terminologies include:

| Adhesive failure |

A failure mode in which the seal fails at the original interface between the surfaces being sealed. |

| Burnthrough |

A state or condition of a heat seal characterised by melted holes and thermal distortion. If this occurs it is normally due to the heat or sealing time of the sealing bars. |

| Cohesive failure |

A failure mode where the specimen splits parallel to the seal and the seal itself stays in-tact. |

| Cooling curve |

The graph of the increase in strength of the seal with time, as it cools in the period directly after the sealing cycle. Basically it is a graph of hot seal strength versus cooling time. |

| Cooling time |

The time interval from the conclusion of the heat seal to the determination of the hot tack force. |

| Delay time |

The time interval from when the heat seal jaws open to the onset of the specimen being withdrawn from between the jaws. |

| Dwell time |

The time when the sealing bars are in contact with and applying pressure to the specimen. |

| Failure mode |

A visual determination of the manner in which the test specimen fails. |

| Hot tack |

The strength of a hot seal measured at a specified time after the sealing jaws open but before the seal has had time to reach ambient temperature. |

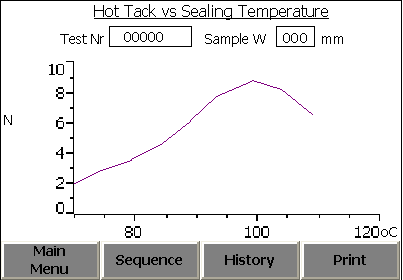

| Hot tack curve |

A graph of hot tack strength versus sealing temperature. |

| Sealing Temperature |

Maximum temperature reached at the interface between the two web surfaces being sealed, during the dwell time of the cycle. |

| Withdrawal time |

The time when withdrawal of the sample from between the jaws is initiated until such a time where it is taught between the specimen clamps. It is at this time when determination of the strength of the seal begins. |

Hot Tack tester Operation

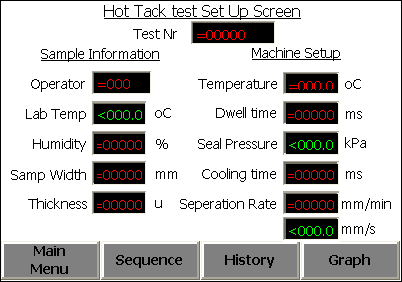

The Hot tack test setup page is used to allow the operator to enter the required parameters of a test. These include:

- Test Nr

- Thickness

- Operator

- Temperature

- Lab Temp

- Dwell time

- Humidity

- Seal pressure

- Sample Width

- Cooling time

- Separation rate

Once the test parameters have been selected by the operator, the sample strip can be loaded into the sample clamps before pressing Start at which stage the Hot Tack Tester automatically places the sample between the heated sealing jaws, closing the jaws for the preselected time in milliseconds, removing the sealed sample strip and, with no delay, begins the peeling process.

The Hot Tack Test prompt page will appear after a Sample test has been completed. The Operator must then enter the Failure Mode. The standard points out that a number of different failure modes could occur in the course of the failure of the strip, the Hot Tack Tester allows an operator to enter one of seven Failure modes. If the operator is not satisfied, then the Repeat Cycle button can be touched, the test will not record any results and the Cycle and Sample number will remain the same.

Test Results

The Hot Tack Graph page displays the Mean average values from each cycle, it is used to see whether a trend is occurring in relation to highest recorded force applied versus the Sealing temperature. The Results can be printed by touching the Print button; the graph will be printed followed by a report detailing all the test results.

Easy Calibration

The Calibration Menu allows access to items that require adjustment from time to time. Simply touch the required button to move to the desired pages of calibration within the software.