The Gardner Type Impact Tester can rank materials according to the force required to break flat, rigid plastic samples. This is under specific conditions of impact of a striker and a falling weight.

Features of the Gardner Type Impact Tester

- Bench mounted operation

- Heavy duty base to withstand the impact shock

- Steel rod impact mass

- Specimen support plate

- Hardened steel striker with a rounded nose

- Weights: 0.9kg (2Lb), 1.8kg (4Lb) and 3.6kg (8Lb)

- Slotted guide tube (1.0m / 40” in length), in which the impact mass slides.

- Bracket holds the tube in a vertical position by attaching it to the base

- Bracket holds the pivot arm alignment for the striker, about 50mm / 2” under the tube.

- For Geometries GA, GB and GC, a specimen of 15.86mm ± 0.1mm (0.625” ± 0.004”)

- With Geometries GA and GD, a specimen support plate with a hole 76mm ± 3.0mm (3.0” ± 0.12”) in diameter is mounted in the apparatus.

Summary of Gardner Type Impact Test

The procedure to determine the energy (mass x gravity x height) that will cause 50% of specimens to fail is such that a weight falls through a guide tube and impacts a striker resting on a supported specimen.

The height the weight falls from is adjustable and the test also permits various striker and support plate changes. These variances allow different modes of failure, easier sampling or limit the amount of testing material.

Significance and use of the test

The significance of subjecting samples of plastics to the impact test is that different materials respond differently to changes in velocity of impact due to the fact that plastics are viscoelastic.

Interferences

Impact values cannot be considered absolute unless the geometry of the test equipment and specimen conform to the end use requirement. Data obtained with different geometries, (see Page 7) cannot, in general, be compared directly with each other. Falling-weight-impact results are not suitable for predicting the relative ranking of materials at impact velocities differing greatly from those imposed by the Gardner Impact method.

As cracks usually start at the surface opposite the one that is struck, the results obtained can be greatly influenced by the quality of the test specimens. Flaws in this surface will also affect results. Impact properties of plastic materials can be very sensitive to temperature. The Gardner Type Impact tester can perform tests in any reasonable temperature and/or environment. The apparatus supplied and suggested may not have sufficient energy to cause failure of some specimens under the conditions set out in the relevant standards.

Tester Apparatus

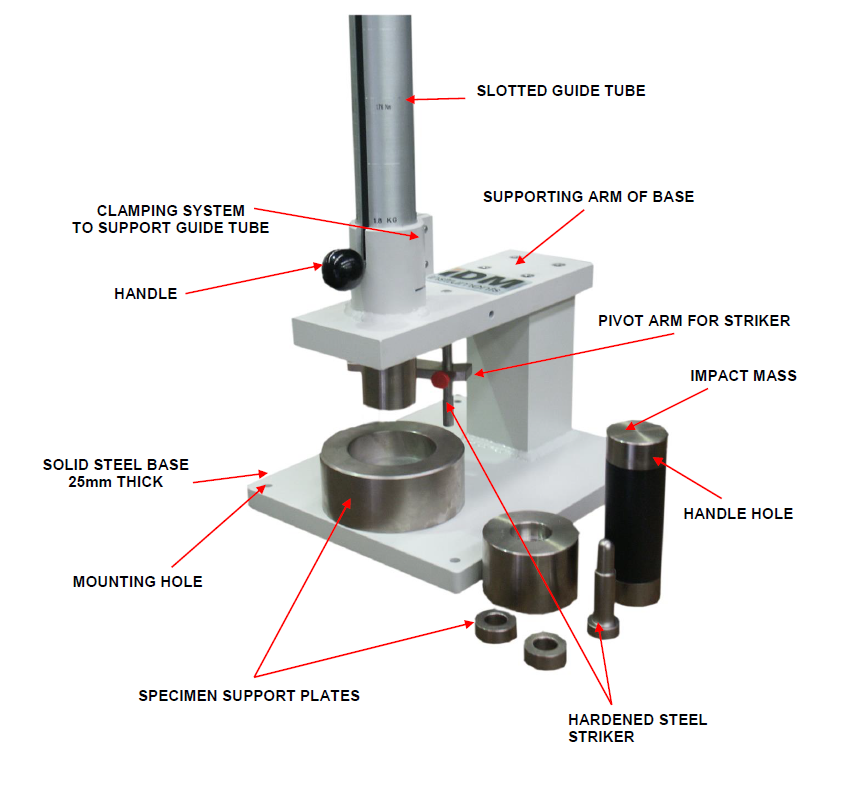

The Gardner Type Impact Tester consists of the following:

- A suitable base to withstand the impact shock.

- 2 Steel rod impact masses weighing 0.9kg and 1.8kg .

- 2 Hardened steel strikers having rounded nose diameters of 15.86 ± 0.10mm and 12.70 ± 0.10mm.

- A slotted guide tube of 1.2m in length in which the mass slides, having graduations of 10mm.

- A clamping system to hold the tube vertically in the supporting arm of the base.

- A holder for the hand knob which in turn acts as a pivot arm alignment.

- A pivot arm for the striker, which is located about 50mm under the tube.

- 2 Specimen support plates with hole diameters of 76.0mm ± 3.0mm and 31.75mm ± 0.025mm both of which have a rounded top edge of the opening at 1.0mm ± 0.2 mm

- 2 Specimen support plates with hole diameters of 16.26 ± 0.025mm, one of which has a rounded top edge of the opening at 1.0mm ± 0.2 mm and the other at 0.75mm.

To minimise the energy absorption, compression, and deflection of the support, the tester should be fixed to a dense, solid base weighing a minimum of 181.00 kg. by way of mounting holes on each corner.

Test Specimens

Test specimens and sample should be prepared with the following in mind:

- Free from obvious defects and imperfections unless required.

- At least 25mm greater than the diameter in the hole in the support plate.

- The thickness shall not differ more than 5% from the average specimen thickness of that sample.

- Machining specimens to reduce thickness variation is not acceptable.

- 20 specimens will usually yield sufficient results unless the approximate mean failure height is not known. In this case, six additional specimens should be used to determine the appropriate starting point of the test.

- Prepare the specimen so that there is little effect on the impact resistance.

Defintions

Failure: the presence of any crack or split created by the impact of the falling weight that can be seen by the naked eye or under normal laboratory lighting conditions:- such as

- Complete shattering of the sample

- Any crack radiating out towards the edge on either surface of the sample

- Any radial crack within or just outside the impact area of the striker

- Any hole where unobstructed light or water could pass through

- Any brittle splitting of the bottom surface

- Any glassy type chip dislodges or loosens

Penetrating Dye: used to differentiate incipient cracking in glass reinforced polymers where it is difficult to interpret cracks from reinforcing fibres

Mean-failure Energy: the energy required to produce 50% failures, equal to the product of the constant mass and mean failure height.

Mean-failure Height: the height at which a standard mass, when dropped on the test specimens, will cause 50% failures.